-

Gat No 611 , Mouje-Kuruli, MIDC Chakan, Tal-khed Pune - 410501

Email Id - uday@excelplants.com

CallUs - +91-09225776611

OUR PRODUCTS - Industrial Evaporators

Excel plants is the leading design manufacturing and supplier of the multiple effect evaporation systems for dairy,

food processing, pharmaceuticals, chemicals, ETP, agrochemicals and allied products etc.

TYPES OF EVAPORATORS :

• Falling Film Evaporator,Rising Film Evaporator, Forced Circulation Evaporator,

Scrapped Surface / Thin film Evaporator, Combination Evaporator,

Evaporative Crystallizers, Flash Evaporator, Wiped Film Evaporator.

CRITERIA FOR SELECTION :

• Nature of Product,Scaling Tendency, Heat Sensitivity, Foaming Tendency,

Viscosity of product,

Thermal Characteristics of Product,

Degree of Concentration,

Evaporation Rate.

Applications :

+ Dairy & Food Products :Milk, Honey, Whey, Fruit Juices, Tomato Juice, Malt

Extract, Sugar Cane Juice, Invert Sugar, Coffee

Extract, Tea Extract, Tannin Extract, Dextrose/Fructose,

Herbal Extract.

Chemical & Pharmaceuticals :Spent Wash, Black Liquor, Salt, Amino Acid, Enzymes, Gelatine/Glue, Sodium Sulphate, Katha & Kutch, Dye, Dye Intermediaries, Effluent, Caustic Soda, Phosphoric Acid etc.

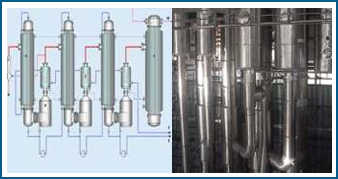

⇓ Falling Film Evaporators

Equipped with compact design, low building cost and continuous operation, our falling film evaporators are best suitable for heat sensitive products. Having falling film design, these exhibit the following features:

Equipped with compact design, low building cost and continuous operation, our falling film evaporators are best suitable for heat sensitive products. Having falling film design, these exhibit the following features:

• Easy operation

• Automatic controls

• Concentration ready on start of plant

• CIP cleaning so less chemical consumption

• Gentle heating of products

• Low hold up of products in plant

• Capacity available in various sizes and stages

• Multistage with low steam consumption

• Plants are with thermal vapor recompress or (TVR)

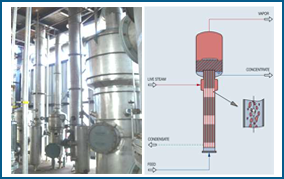

⇓ Rising Film Evaporators :

In a Rising Film Evaporator liquid feed enters from the bottom of steam heated tubes. The parallel movement of liquid and vapor along tube surface imparts effective water evaporation from the liquid feed. This type of evaporator is ideal for liquids which attain high viscosity or have fouling tendency.

⇓ Forced Circulation Evaporators::

This is ideal for concentration of high viscous material and products with higher solids. This is also used as evaporative crystallizer. Sometimes these are used in series with falling film evaporator as finishing effect for achieving higher concentration.

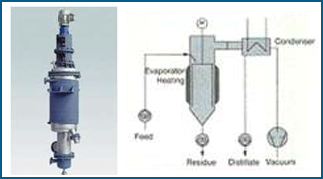

⇓ Agitated Thin Film Evaporators :

The agitated thin film evaporator is well suited for concentration of viscous and heat sensitive liquids such as gelatin, antibiotics, fruit juices, and solvent mix etc. The thin film evaporator reduces fouling and liquid residence time in the evaporator. In the vertical agitated thin film evaporator feed liquid is feed at the top of evaporator and is uniformly distributed in the form of thin film by the wiper blades on vertical cylindrical heat transfer area, inside the unit. Evaporation of water / solvent takes place as the thin film moves down the heat transfer area.

⇓ Scrapped Surface/ Thin Film Evaporators :

Scrapped Surface/Thin Film Evaporator are designed for evaporation of highly viscous and sticky products, which cannot be otherwise evaporated. This type of evaporators have been specially designed to provide high degree of agitation, effecting heat transfer as well as scrapping the walls of the evaporator to prevent deposition and subsequent charring of the product.